|

Equipment |

No. |

Parameter |

QTY |

|||

|

500(kg/h) |

1000(kg/h) |

2000(kg/h) |

3000(kg/h) |

|||

|

Alkali dissolving tank |

1 |

500L |

1000L |

2000L |

3000L |

1 |

|

Oil saponification pot |

2 |

1000L |

2000L |

4000L |

6000L |

1 |

|

Caustic soda pipe valve |

3 |

nil |

nil |

nil |

nil |

1 |

|

Water pipe valve |

4 |

nil |

nil |

nil |

nil |

1 |

|

Steam pipe valve |

5 |

nil |

nil |

nil |

nil |

1 |

|

Batching mixing tank |

6 |

500L |

1000L |

2000L |

3000L |

1 |

|

Effervescent alkali tank |

7 |

500L |

1000L |

2000L |

3000L |

1 |

|

Tube heater |

8 |

380V |

380V |

380V |

380V |

1 |

|

Vacuum drying chamber |

9 |

3m3 |

4m3 |

5m3 |

6m3 |

1 |

|

Vacuum granulator |

10 |

500kg/h |

1000kg/h |

2000kg/h |

3000kg/h |

1 |

|

Cyclone separator |

11 |

380v |

380v |

380v |

380v |

1 |

|

High pressure jet pump |

12 |

4kw |

5.5kw |

7.5kw |

11kw |

1 |

|

Atmospheric condenser |

13 |

380v |

380v |

380v |

380v |

1 |

|

Steam water separator |

14 |

380v |

380v |

380v |

380v |

1 |

|

Conveyor |

15 |

380v |

380v |

380v |

380v |

1 |

|

Three roll grinder |

16 |

500kg/h |

1000kg/h |

2000kg/h |

3000kg/h |

1 |

|

Vacuum stripper |

17 |

500kg/h |

1000kg/h |

2000kg/h |

3000kg/h |

1 |

|

Circulating submersible pump |

18 |

nil |

nil |

nil |

nil |

1 |

|

Block cutting roller printing machine |

19 |

500kg/h |

1000kg/h |

2000kg/h |

3000kg/h |

1 |

|

Finished product conveyor belt |

20 |

380v |

380v |

380v |

380v |

1 |

|

Vacuum pump |

21 |

380v |

380v |

380v |

380v |

1 |

|

Gas fired boiler |

22 |

1T |

1T |

2T |

3T |

1 |

No. 188, Hongshan Road, Changsha City, Hunan Province

一、Oil Saponification Soap Production Equipment

1、Design Description

This set of production line is from oil melting, oil saponification, salt washing, alkali washing, bleaching, finishing, vacuum granulation, one-time grinding, continuous vacuum double barrel double strip, cutting and forming (the most advanced process at home and abroad). It has the characteristics of less land occupation, low consumption, less employment and stable product quality, and can produce a variety of soap products (high, medium and low-grade products) with fatty acid content ranging from 38% to 70%.

2、Production Condition

|

Capacity (kg/h) |

Area (m2 ) |

Height (m) |

Labor |

Water, electricity and gas consumption |

||

|

Water (m3/h)

|

Electricity (kw/h)

|

Gas (m3/h)

|

||||

|

500 |

300 |

4 |

3-5 |

2 |

30 |

2 |

|

1000 |

500 |

4 |

5-8 |

4 |

50 |

4 |

|

2000 |

800 |

4.5 |

8-10 |

6 |

80 |

8 |

|

3000 |

1000 |

5 |

10-12 |

8 |

100 |

12 |

3、Equipment Configuration and Parameter

|

Equipment |

No. |

Parameter |

QTY |

|||

|

500(kg/h) |

1000(kg/h) |

2000(kg/h) |

3000(kg/h) |

|||

|

Alkali dissolving tank |

1 |

500L |

1000L |

2000L |

3000L |

1 |

|

Oil saponification pot |

2 |

1000L |

2000L |

4000L |

6000L |

1 |

|

Caustic soda pipe valve |

3 |

nil |

nil |

nil |

nil |

1 |

|

Water pipe valve |

4 |

nil |

nil |

nil |

nil |

1 |

|

Steam pipe valve |

5 |

nil |

nil |

nil |

nil |

1 |

|

Batching mixing tank |

6 |

500L |

1000L |

2000L |

3000L |

1 |

|

Effervescent alkali tank |

7 |

500L |

1000L |

2000L |

3000L |

1 |

|

Tube heater |

8 |

380V |

380V |

380V |

380V |

1 |

|

Vacuum drying chamber |

9 |

3m3 |

4m3 |

5m3 |

6m3 |

1 |

|

Vacuum granulator |

10 |

500kg/h |

1000kg/h |

2000kg/h |

3000kg/h |

1 |

|

Cyclone separator |

11 |

380v |

380v |

380v |

380v |

1 |

|

High pressure jet pump |

12 |

4kw |

5.5kw |

7.5kw |

11kw |

1 |

|

Atmospheric condenser |

13 |

380v |

380v |

380v |

380v |

1 |

|

Steam water separator |

14 |

380v |

380v |

380v |

380v |

1 |

|

Conveyor |

15 |

380v |

380v |

380v |

380v |

1 |

|

Three roll grinder |

16 |

500kg/h |

1000kg/h |

2000kg/h |

3000kg/h |

1 |

|

Vacuum stripper |

17 |

500kg/h |

1000kg/h |

2000kg/h |

3000kg/h |

1 |

|

Circulating submersible pump |

18 |

nil |

nil |

nil |

nil |

1 |

|

Block cutting roller printing machine |

19 |

500kg/h |

1000kg/h |

2000kg/h |

3000kg/h |

1 |

|

Finished product conveyor belt |

20 |

380v |

380v |

380v |

380v |

1 |

|

Vacuum pump |

21 |

380v |

380v |

380v |

380v |

1 |

|

Gas fired boiler |

22 |

1T |

1T |

2T |

3T |

1 |

4、Production Line

(1) Alkali dissolving tank; (2) Oil saponification pot; (3) Caustic soda pipe valve; (4) Water pipe valve; (5) Steam pipe valve; (6) Batching and blending tank; (7) Bubble alkali tank; (8) Tube heater; (9) Vacuum drying chamber; (10) Vacuum granulator; (11) Cyclone separator; (12) High pressure jet pump; (13) Atmospheric condenser; (14) Steam water separator; (15) Conveyor belt; (16) Three roll grinder; (17) Up and down vacuum stripper; (18) Circulating submersible pump; (19) Block cutting roller printing machine; (20) Finished product conveyor belt; (21) vacuum pump.

|

|

|

|

|

|

8-Tube heater |

11- Cyclone separator |

10- Granulator |

1-Alkali dissolving tank |

|

|

|

|

|

|

6- Batching pot |

13-Atmospheric condenser |

21-Vacuum pump |

2- Saponification pot |

|

|

|

|

|

|

9- Vacuum drying chamber |

14-Steam water separator |

Control box |

20-Conveyor |

|

|

|

|

|

|

16-Three roll grinder |

17-Vacuum stripper |

19-Cutting machine |

21-Roots vacuum pump |

5、Production Materials

|

Materials Types |

Material Name |

|

Animal oil |

Any two or more of butter, mutton oil, lard, chicken and duck oil, bone oil, gutter oil, etc |

|

Vegetable oil |

Any two or more of cotton seed oil, sunflower seed oil, palm oil, coconut oil, coconut acid and other plants |

|

Others |

Caustic soda, sodium silicate, salt, bleaching liquid, essence and soap yellow |

6、Equipment accessories

Pipes and valves: one batch

Oil processing pool: on site

7、Oil Saponification Equipment Price

7.1:The investment of semi-automatic production line is about ¥150000-250000.

7.2:The investment of automatic production line is about ¥500000-1200000 according to different output.

二、Soap production equipment

1、Three-roll Grinder

|

Equipment |

Application range |

Feature |

Remarks |

|

FDYM200 Three-roll Grinder |

150kg/h Suitable for experimental production |

20% higher output service life up to more than 8 years |

According to actual needs choose one from them |

|

FDYM260 Three-roll Grinder |

500kg/h Suitable for medium/ small-scale production |

20% higher output service life up to more than 8 years |

|

|

FDYM315 Three-roll Grinder |

600kg/h Suitable for medium scale production |

20% higher output service life up to more than 8 years |

|

|

FDYM405 Three-roll Grinder |

850kg/h Suitable for medium/large scale production |

20% higher output service life up to more than 8 years |

|

|

FDYM405+ Three-roll Grinder |

1000kg/h Suitable for large scale production |

20% higher output service life up to more than 8 years |

|

|

|

|

|

FDYM200 Three-roll Grinder |

FDYM315 Three-roll Grinder |

FDYM405 Three-roll Grinder |

2、Vacuum Plodder

|

Equipment |

Application range |

Feature |

Remarks |

|

FDCT300A Vacuum Plodder |

300kg/h Suitable for small scale production |

Carbon steel Weight: 1800kg Power:13kw Voltage: 380v/50HZ |

According to actual needs choose one from them |

|

FDCT300B Vacuum Plodder |

300kg/h Suitable for small scale production |

Stainless steel 1800kg Power:13kw Voltage: 380v/50HZ |

|

|

FDCT500A Vacuum Plodder |

500kg/h Suitable for medium scale production |

Carbon steel Weight: 2500kg Power:18.5kw Voltage: 380v/50HZ |

|

|

FDCT500B Vacuum Plodder |

500kg/h Suitable for medium scale production |

Stainless steel Weight: 2500kg Power:18.5kw Voltage: 380v/50HZ |

|

|

FDCT1000A Vacuum Plodder |

1000kg/h Suitable for large scale production |

Carbon steel Weight: 3500kg Power:22kw 380v/50HZ |

|

|

FDCT1000B Vacuum Plodder |

1000kg/h Suitable for large scale production |

Stainless steel Weight: 3500kg Power:22kw Voltage: 380v/50HZ |

|

|

|

|

FDCT00A Vacuum Plodder |

FDCT00B Vacuum Plodder |

3、Cutting Machine

|

Equipment |

Application range |

Feature |

Remarks |

|

FDQK01 Cutting Machine |

Suitable for small scale production |

Manual cutting No electricity required |

According to actual needs choose one from them |

|

FDQK02 Cutting Machine |

Suitable for medium/large scale production |

Automatic pneumatic cutting b------lock Easy to operate 30% Speed increased by 30% |

|

|

FDQK03 Cutting Machine |

Suitable for medium/large scale production |

Automatic electronic cutting Fast cutting Convenient adjustment |

|

|

|

|

|

FDQK01 Cutting Machine |

FDQK02 Cutting Machine |

FDQK03 Cutting Machine |

4、Others

|

Equipment |

Feature |

|

FDSS01 Conveyor |

304 Stainless steel |

|

FDZKB01 Vacuum Pump |

Speed increased by 30% |

|

FDSS06 Conveyor |

304 Stainless steel |

|

FDKZ01 Control Box |

All in one control box |

|

|

|

|

|

|

FDPT01 Work Platform |

FDSS01 Conveyor |

FDZKB01 Vacuum Pump |

FDKZ01 Control Box |

5、Production Materials

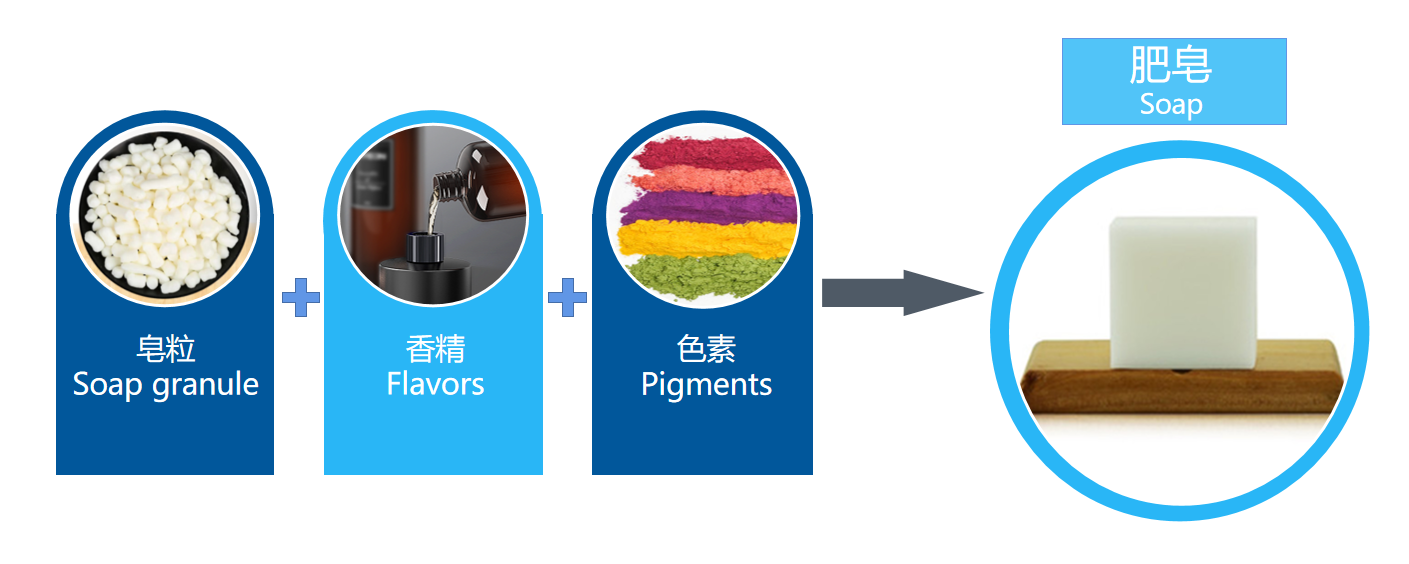

6、Products can be produced

7、User cases

8、Soap equipment price

8.1、The investment of semi-automatic production line is about ¥80000-120000.

8.2、The investment of automatic production line is about¥150000-300000 according to different output.

三、Perfumed Soap Production Equipment

1、Material Mixer

|

Equipment |

Application range |

Feature |

Remarks |

|

FDJB01 Material Mixer |

Suitable for mixing 50kg/time |

Dust proof bearing box 304 Stainless steel |

According to actual needs choose one from them |

|

FDJB02 Material Mixer |

Suitable for mixing 100kg/time |

Dust proof bearing box 304 Stainless steel |

|

|

FDJB03 Material Mixer |

Suitable for mixing 200kg/time |

Dust proof bearing box 304 Stainless steel |

|

|

|

|

|

FDJB01 Material Mixer |

FDJB02 Material Mixer |

FDJB03 Material Mixer |

2、Three-roll Grinder

Refer to three-roll grinder configure in soap production line.

3、Vacuum Plodder

Refer to vacuum plodder configure in soap production line.

4、Cutting Machine

Refer to cutting machine configure in soap production line.

5、Soap Printer

|

Equipment |

Application range |

Feature |

Remarks |

|

FDDY01 Soap Printer |

Suitable for small scale production |

Semi automatic soap printing Manually put and take soap |

According to actual needs choose one from them |

|

FDDY02 Soap Printer |

Suitable for medium/large scale production |

Automatic soap printer |

|

|

FDDY03 Soap Printer |

Suitable for medium/large scale production |

Automatic soap printer |

|

|

|

|

|

FDDY01 Soap Printer |

FDDY02 Soap Printer |

FDDY03 Soap Printer |

6、Others

|

Equipment |

Feature |

|

FDPT01 Work Platform |

304Stainless steel Anti-slide plate durable |

|

FDSS01 Conveyor |

304 Stainless steel |

|

FDLD01 Freezer |

30% reduction in cooling time |

|

FDZKB01 Vacuum Pump |

Speed increased by 30% |

|

FDSS06 Conveyor |

304 Stainless steel |

|

FDKZ01 Control Box |

All in one control box |

|

|

|

|

|

|

FDPT01 Work Platform |

FDSS01 Conveyor |

FDLD01 Freezer |

FDZKB01 Vacuum Pump |

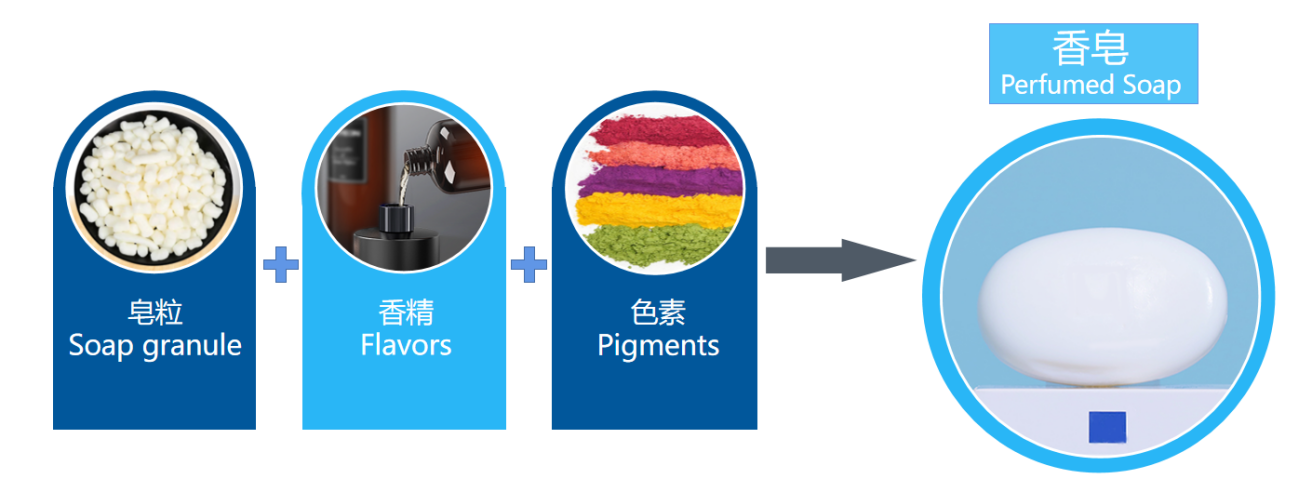

7、Production Materials

8、Products can be produced

9、Perfumed soap equipment price

10.1、The investment of semi-automatic production line is about ¥200000.

10.2、The investment of automatic production line is about ¥300000-600000 according to different output.

|

Equipment |

No. |

Model |

Capacity |

Volt/Freq |

Qty |

Price |

|

Work Platform |

1 |

FDPT01 |

nil |

nil |

1 |

1000/m2 |

|

Material Mixer |

2 |

FDJB50 |

100-300kg/h |

380V/50Hz |

Choose one of them |

12000 |

|

FDJB100 |

300-500kg/h |

380V/51Hz |

18000 |

|||

|

FDJB200 |

500-1000kg/h |

380V/52Hz |

30000 |

|||

|

Three-roll Grinder |

3 |

FDYM65-30 |

30kg/H |

380V/50Hz |

Choose one of them |

16800 |

|

FDYM100-50 |

50kg/H |

380V/50Hz |

17300 |

|||

|

FDYM150-80 |

80kg/H |

380V/50Hz |

18000 |

|||

|

FDYM200-150 |

150kg/H |

380V/50Hz |

32000 |

|||

|

FDYM260-500 |

500kg/H |

380V/50Hz |

41000 |

|||

|

FDYM315-600 |

600kg/H |

380V/50Hz |

55000 |

|||

|

FDYM405-850 |

850kg/H |

380V/50Hz |

68000 |

|||

|

FDYM405+1000 |

1000kg/H |

380V/50Hz |

82000 |

|||

|

Conveyor |

4 |

FDSS01 |

nil |

380V/50Hz |

1 |

9800 |

|

Freezer |

5 |

FDLD01 |

nil |

380V/50Hz |

1 |

25000 |

|

Vacuum Plodder |

6 |

FDCT100A |

100kg/H |

380V/50Hz |

Choose one of them |

50000 |

|

FDCT300A |

300kg/H,Carbon steel |

380V/50Hz |

70000 |

|||

|

FDCT300B |

300kg/H,Stainless steel |

380V/50Hz |

80000 |

|||

|

FDCT500A |

500kg/H,Carbon steel |

380V/50Hz |

100000 |

|||

|

FDCT500B |

500kg/H,Stainless steel |

380V/50Hz |

120000 |

|||

|

FDCT1000A |

1000kg/H,Carbon steel |

380V/50Hz |

120000 |

|||

|

FDCT1000B |

1000kg/H,Stainless steel |

380V/50Hz |

160000 |

|||

|

Vacuum Pump |

7 |

FDZKB01 |

nil |

380V/50Hz |

1 |

3900 |

|

Cutting Machine |

8 |

FDQK01 |

Hand cutting |

380V/50Hz |

Choose one of them |

free |

|

FDQK02 |

Pneumatic cutting |

380V/50Hz |

19800 |

|||

|

FDQK03 |

Electron slicing |

380V/50Hz |

39800 |

|||

|

Soap Printer |

9 |

FDDY01 |

semi-automatic |

380V/50Hz |

Choose one of them |

19800 |

|

FDDY02 |

Fully automatic one for one |

380V/50Hz |

85000 |

|||

|

FDDY03 |

Fully automatic one to three |

380V/50Hz |

180000 |

|||

|

Conveyor |

10 |

FDSS06 |

nil |

380V/50Hz |

1 |

7000 |

|

Factory price: |

¥ |

|||||

四、Small-scale Soap Equipment

1、Main Equipment Configuration:

|

Equipment |

Application range |

QTY |

|

Material Mixer |

Laboratory production equipment |

1 |

|

Three-roll Grinder |

Laboratory production equipment |

1 |

|

Vacuum Plodder |

Laboratory production equipment |

1 |

|

Cutting Machine |

Laboratory production equipment |

1 |

|

Soap Printer |

Laboratory production equipment |

1 |

|

Control Box |

Laboratory production equipment |

1 |

|

|

|

|

FDZ-MINI01 Laboratory production equipment |

FDZ-DY01 Soap Printer |

2、Equipment Price

The investment is about ¥80000-180000 according to different equipment configurations.

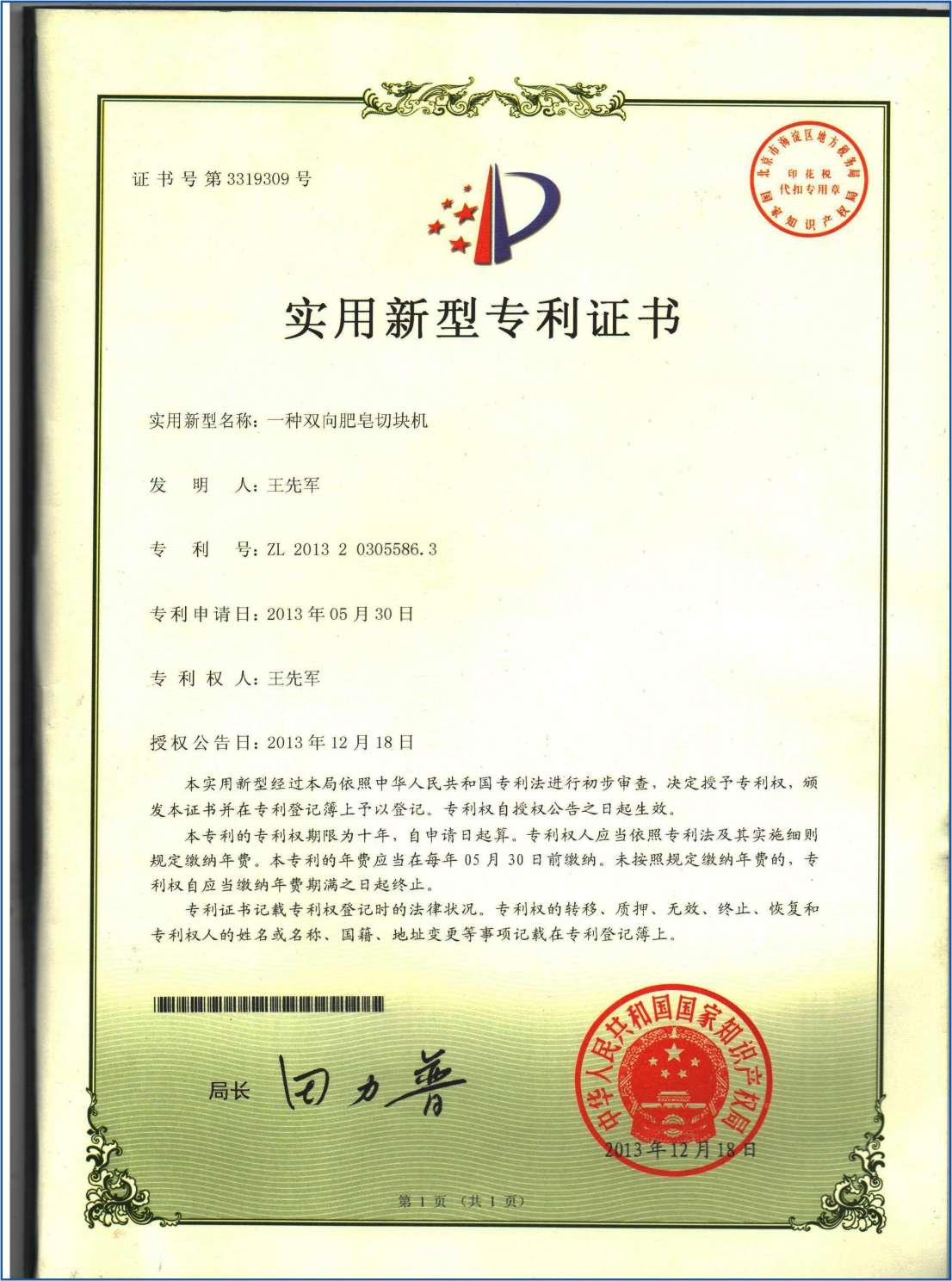

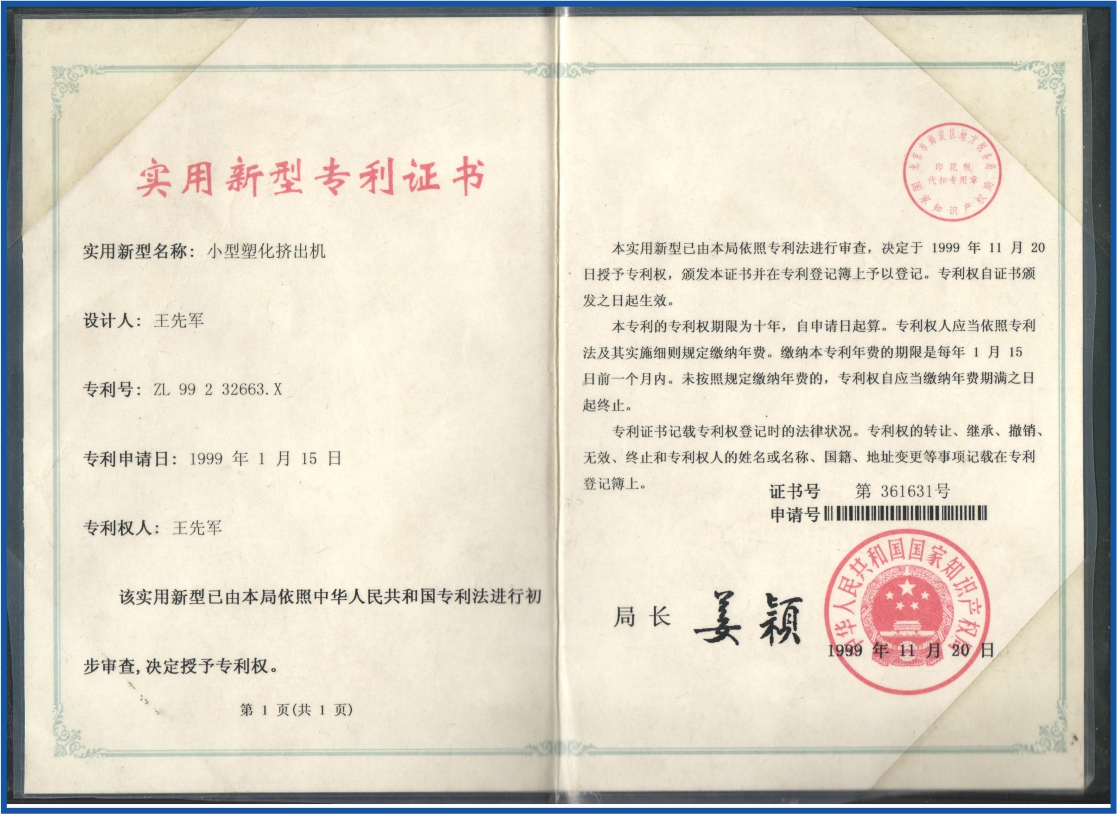

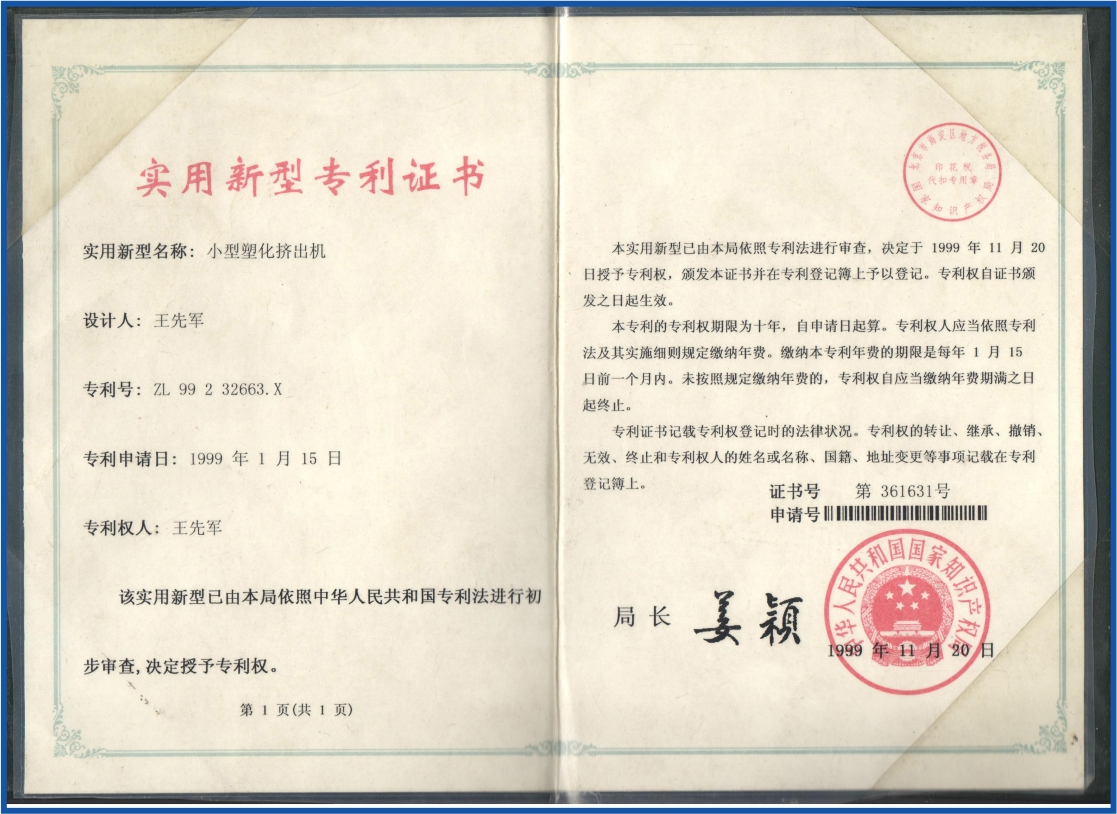

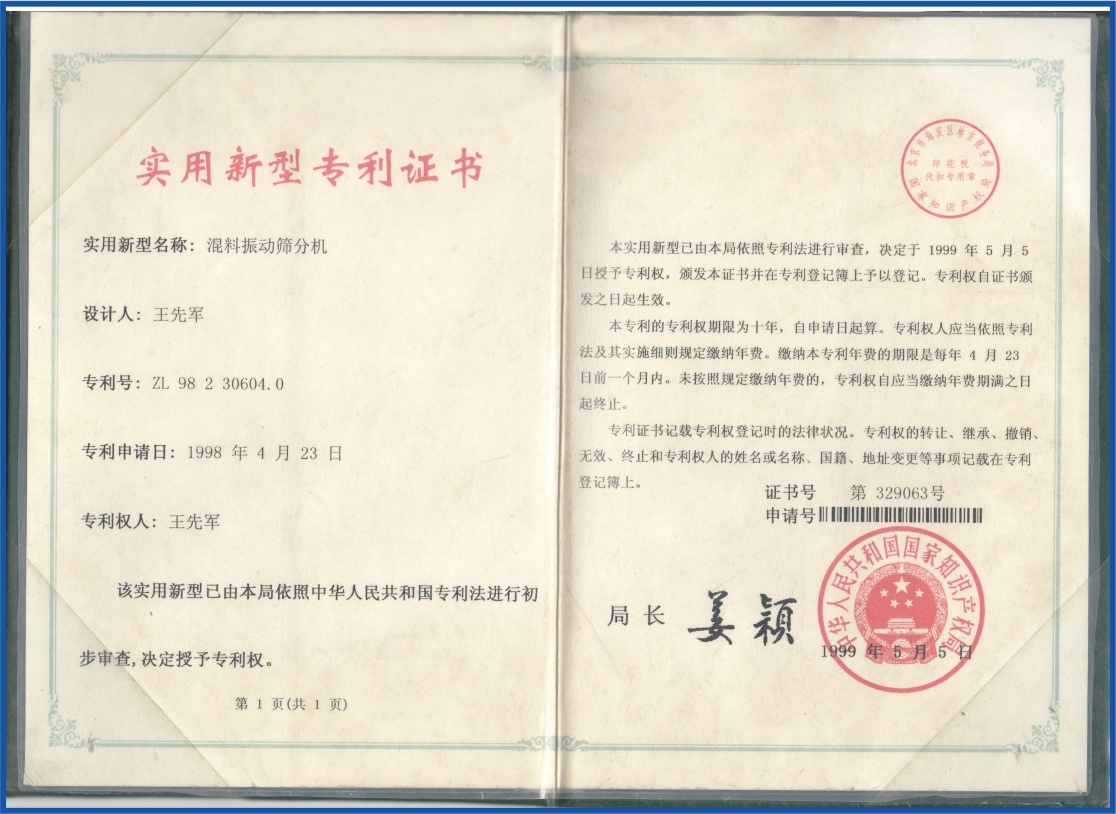

3、Patents

The invention patent of two-way soap cutting machine was obtained on May 30, 2013.

On August 8, 2008, we obtained the invention patent of two-roll pellet molding machine.

The invention patent of soap molding machine was obtained on August 8, 2008.

On January 15, 1999, the invention patent of small plasticizing extruder was obtained.

The invention patent of mixing vibrating screen machine was obtained on April 23, 1998.

4、User cases

|

|

|

|

|

|

|

|

|

|

五、Blue Bubble Toilet Cleaner

1、Refer to the configuration of soap equipment or small-scale soap equipment;

2、The price is from ¥50000 to ¥150000 depends on the output required and the degree of automation;

3、Production cost and sales price:

The cost of 20 small pieces is about ¥1.5-2, and the market price is about ¥5. Every 10000 sets per month will make about¥30000 monthly profit.

4、Production conditions:

Production conditions require more than 20 square meters space, 1-2 labour , more than ¥10000 working capital. The minimum investment in equipment is about ¥50000.

![]()

Global daily chemical production and marketing alliance groupPurpose of this group: integrate daily chemical resources,Le…

To legalize the operation of a daily chemical factory, you need to follow a series of legal and administrative regulation…

Sky eye check ~ Let cheaters nowhere to hide!Through the sky eye check the enterprise, check the boss authenticity, so th…

Six tons volume reactor configuration, equipment volume of 6000 liters, material 304 stainless steel, wall thickness of 5…

Can't wash away the Sharpie e-commerce scam,Beware of being cheatedIn order to help the majority of consumers less detour…